Patents: Table knife

How do you attach the blade of a knife to the handle? This is especially the question with fixed blade knives, and more specifically with table knives. In many cases, the handle is made of a different material than the blade. In attaching the two, you don't want pins or screws. In 1957, the Württembergische Metallwarenfabrik in Geislingen found a solution.

As described in the patent, the blade of a table knife was often fitted with a tang, and the handle was hollow. Molten material was poured into that hilt, into which the tang was then fastened, or the joining material was melted after the blade was set into the hilt. The latter method in particular was a difficult process, and the alloy was relatively expensive.

The solution of German patent 1 067 705 consisted not of another fastening method, but of another material: plastic or synthetic resin. That too, by the way, had been tried before, but in that case the problem was mainly that the molten plastic cooled down very quickly whereas another material, ethoxylin resin, had the disadvantage that it did not bond sufficient with silver, commonly used on table knife handles.

The Württemberg Metalware Factory had discovered a solution, which was to mix ethoxylin resin with quartz sand. This gave a tougher substance and allowed the material to be inserted in the handle, after which the knife was fixed with the blade downwards and the handle was heated. The mixture was not only easier to process, but also gave much better results: the pulling resistance rose from ca. 150 kilo tot 700 or even 900 kilo.

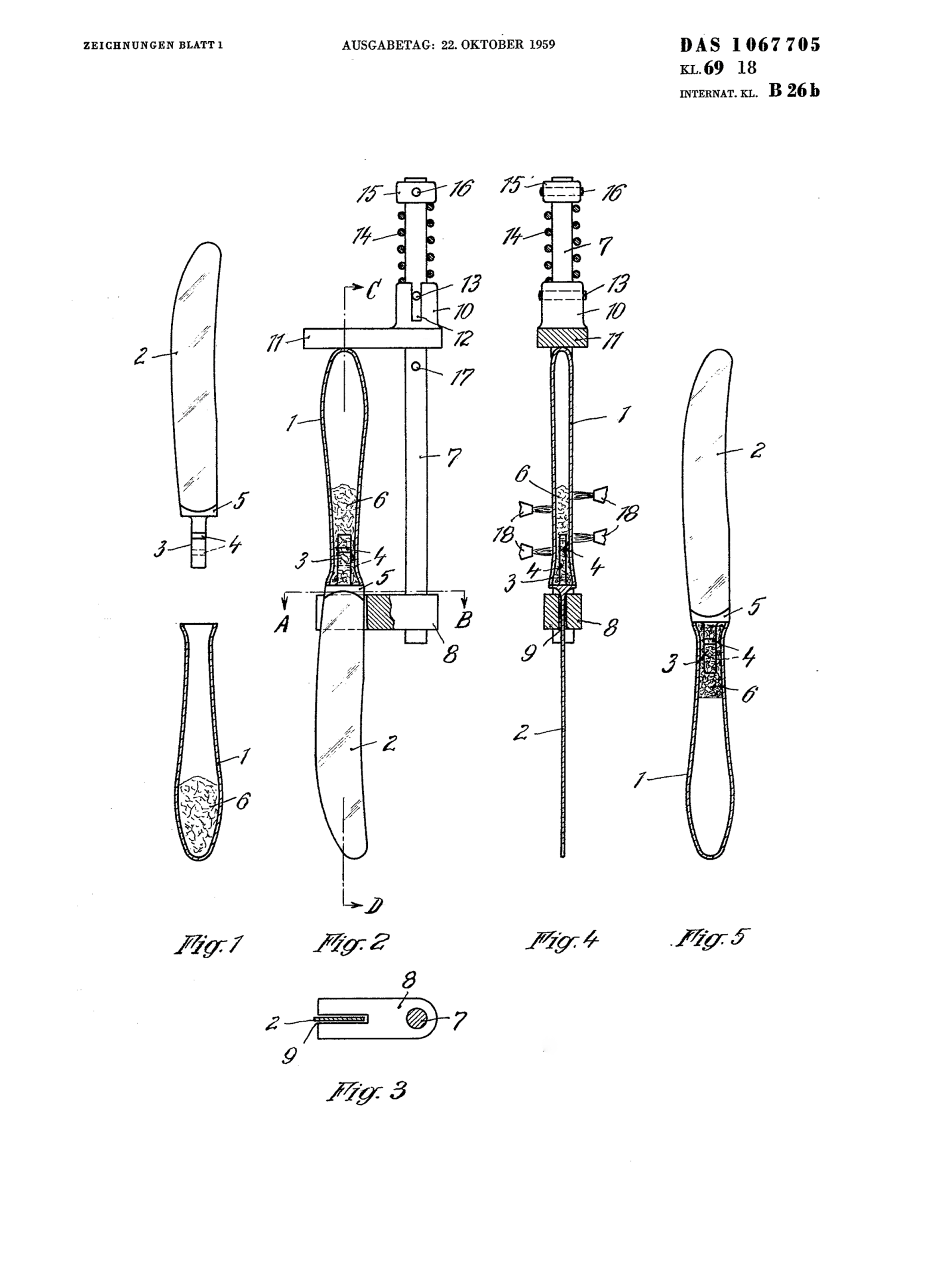

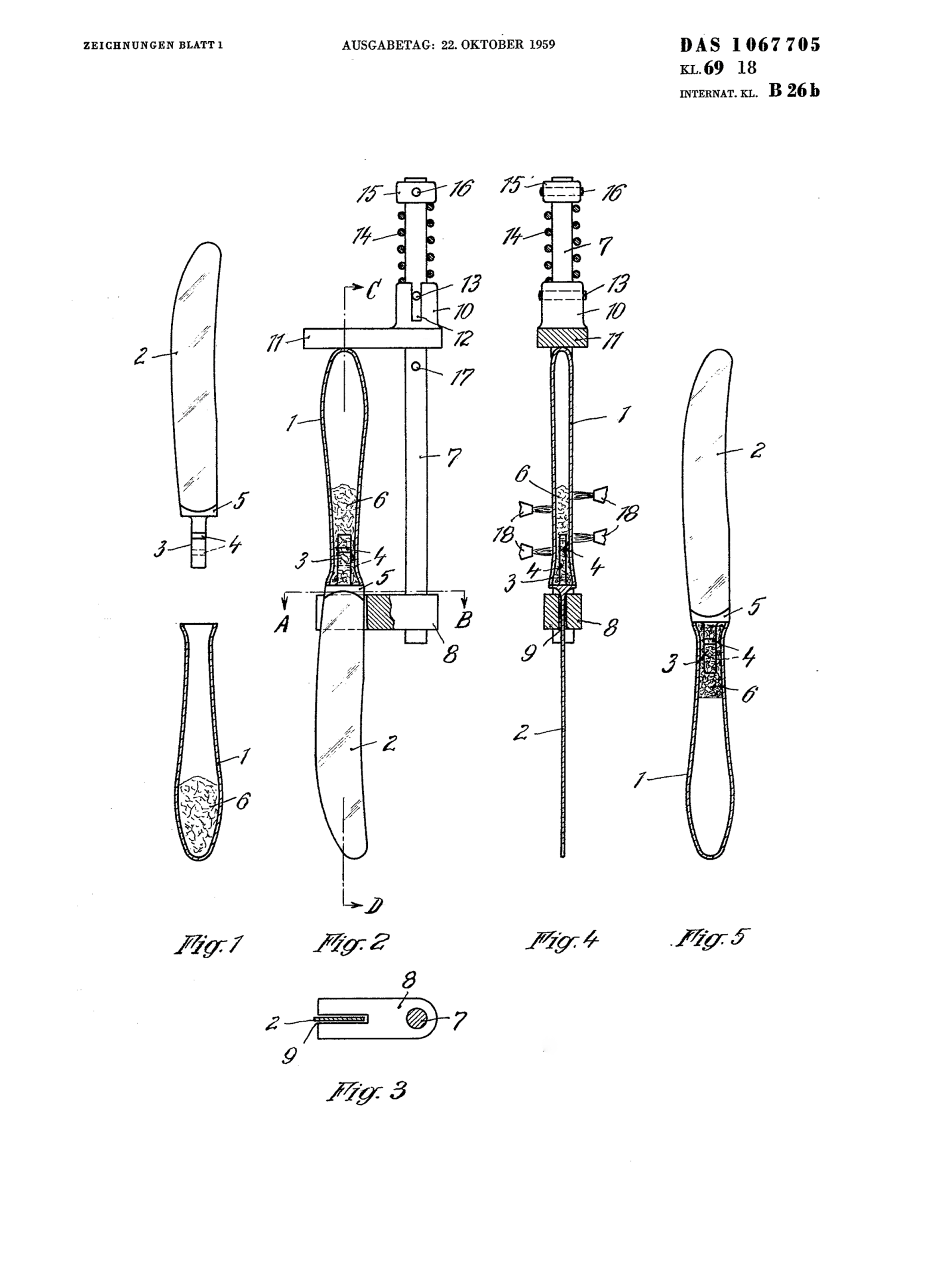

Th patent drawings showed several stages of the process. Fig. I the blade and the handle with the bonding mass; Fig. 2 both connected and placed in a fixture, blade downwards; Fig.4 the heating of the handle and Fig. 5 the finished knife.

The drawings from German patent 1 067 705, with an improved means to fasten a knife

As described in the patent, the blade of a table knife was often fitted with a tang, and the handle was hollow. Molten material was poured into that hilt, into which the tang was then fastened, or the joining material was melted after the blade was set into the hilt. The latter method in particular was a difficult process, and the alloy was relatively expensive.

The solution of German patent 1 067 705 consisted not of another fastening method, but of another material: plastic or synthetic resin. That too, by the way, had been tried before, but in that case the problem was mainly that the molten plastic cooled down very quickly whereas another material, ethoxylin resin, had the disadvantage that it did not bond sufficient with silver, commonly used on table knife handles.

The Württemberg Metalware Factory had discovered a solution, which was to mix ethoxylin resin with quartz sand. This gave a tougher substance and allowed the material to be inserted in the handle, after which the knife was fixed with the blade downwards and the handle was heated. The mixture was not only easier to process, but also gave much better results: the pulling resistance rose from ca. 150 kilo tot 700 or even 900 kilo.

Th patent drawings showed several stages of the process. Fig. I the blade and the handle with the bonding mass; Fig. 2 both connected and placed in a fixture, blade downwards; Fig.4 the heating of the handle and Fig. 5 the finished knife.

The drawings from German patent 1 067 705, with an improved means to fasten a knife

handle to the blade, especially for table knives.