Patents: Federloses Klappmesser

When it comes to making knives, most people think of steel and fire. You need those, of course, but designing a knife lock involves very different aspects as well: mathematics and physics, for example. In 1954, Austrian engineer Theodor Exel used these to design a 'Federloses Klappmesser': a cleverly conceived folding knife, without a spring.

No information on Dipl. Ing. Theodor Exel has been found. Well, we know he was a graduate engineer, living in Kremsmünster, and that between 1949 and 1954, he was granted Austrian patents on four different knife constructions. One involved an annular ferrule to fix the opened blade - four years before that was claimed by Opinel. At issue here is the mechanism of his 'Federloses Klappmesser'.

According to Exel’s patent AT 185267, the principle was as follows: “The present invention relates to springless folding knives and differs from known designs in that the blade foot is given a spiral-shaped boundary with which it rests on a similarly shaped part of the handle when the blade is unfolded, thus limiting unfolding and at the same time preventing unintentional folding of the blade due to the frictional adhesion between the two parts.”

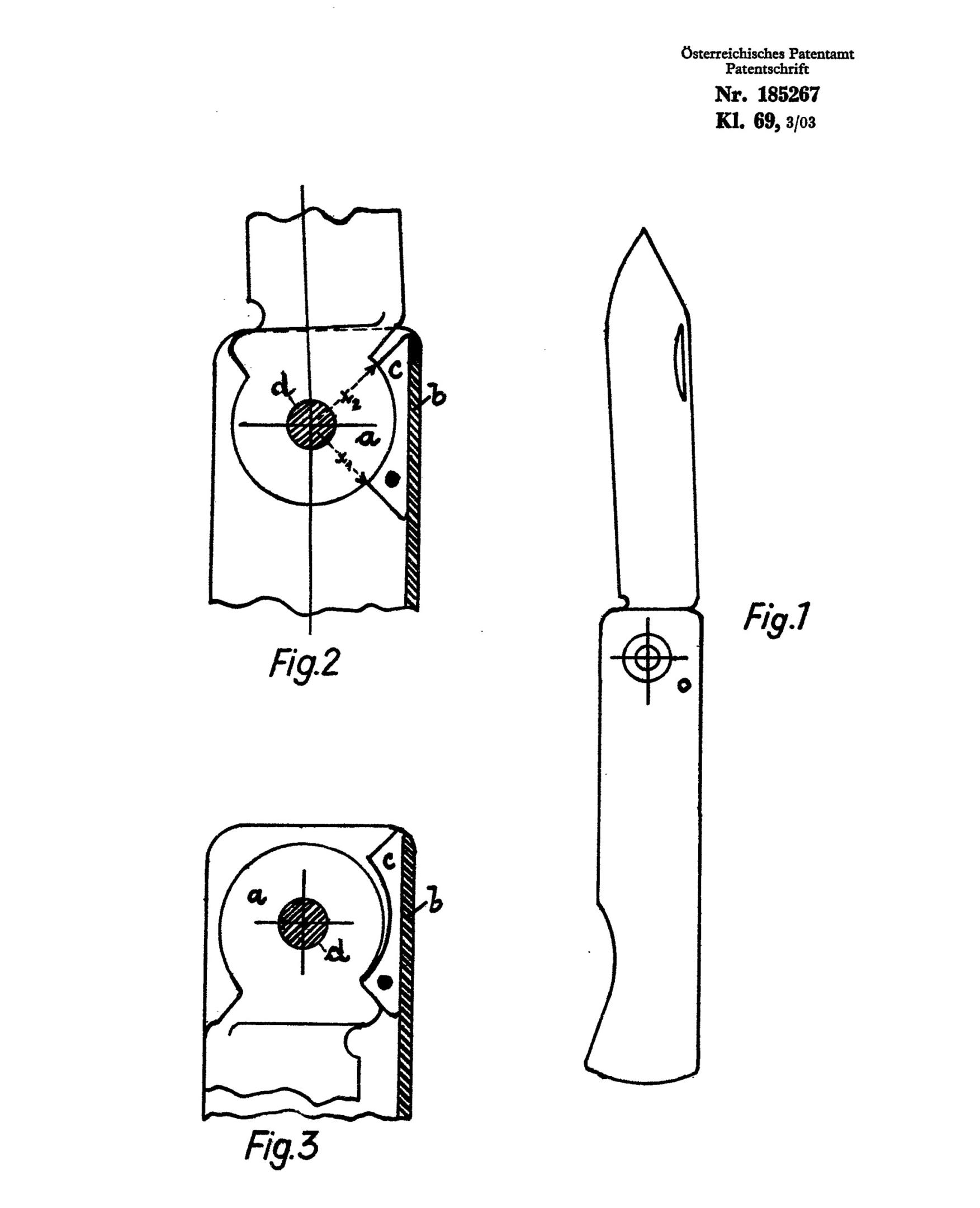

“The characteristic of this new design can be seen in the embodiment shown in Figs. 1-3. Fig. 1 shows the outer view, Fig. 2 and Fig. 3 the front end of the handle and the foot of the folded blade. The foot of the blade a has a spirally ascending shape, so that the dimension nearest the tip of the blade x2 is slightly larger than the dimension x1 further away from the tip of the blade, so that its distance from the hilt rib b or from the intermediate piece c, which rests on the hilt rib, and which is also spirally bounded, decreases when the blade is opened. The radii and the pitch of the spirals, the distance of the pivot pin d from the back of the handle and the width of the intermediate piece c are dimensioned in such a way that the parts a, b and c fit snugly against each other as soon as the blade has reached the use position when unfolded. This stops further rotation of the blade and provides a firm support for the cutting pressure. In the spiral contact surface between the blade base a and the intermediate piece c, this generates a static friction proportional to it, which keeps the blade in its position even after it has stopped. Thus, the greater the cutting pressure, the more the blade is secured against unintentional folding back.”

“[…] The advantages of the new knife, the handling of which does not differ much from the usual one and therefore does not require any change of the user, are therefore the following: The folding up of the blade does not require any appreciable effort, the safety catch is automatically produced by the cutting pressure, and its strength is independent of the degree of any wear, which is hardly to be expected due to the favorable construction, so that the danger of loosening of the connection between blade and hilt and any resulting wobbling of the blade is excluded.”

We do not know if Exel was working with a knife company. His idea still seems very modern, especially in view of the ever stricter bans on knives with a mechanical locking mechanism. Maybe someone picks up on his idea?

No information on Dipl. Ing. Theodor Exel has been found. Well, we know he was a graduate engineer, living in Kremsmünster, and that between 1949 and 1954, he was granted Austrian patents on four different knife constructions. One involved an annular ferrule to fix the opened blade - four years before that was claimed by Opinel. At issue here is the mechanism of his 'Federloses Klappmesser'.

According to Exel’s patent AT 185267, the principle was as follows: “The present invention relates to springless folding knives and differs from known designs in that the blade foot is given a spiral-shaped boundary with which it rests on a similarly shaped part of the handle when the blade is unfolded, thus limiting unfolding and at the same time preventing unintentional folding of the blade due to the frictional adhesion between the two parts.”

“The characteristic of this new design can be seen in the embodiment shown in Figs. 1-3. Fig. 1 shows the outer view, Fig. 2 and Fig. 3 the front end of the handle and the foot of the folded blade. The foot of the blade a has a spirally ascending shape, so that the dimension nearest the tip of the blade x2 is slightly larger than the dimension x1 further away from the tip of the blade, so that its distance from the hilt rib b or from the intermediate piece c, which rests on the hilt rib, and which is also spirally bounded, decreases when the blade is opened. The radii and the pitch of the spirals, the distance of the pivot pin d from the back of the handle and the width of the intermediate piece c are dimensioned in such a way that the parts a, b and c fit snugly against each other as soon as the blade has reached the use position when unfolded. This stops further rotation of the blade and provides a firm support for the cutting pressure. In the spiral contact surface between the blade base a and the intermediate piece c, this generates a static friction proportional to it, which keeps the blade in its position even after it has stopped. Thus, the greater the cutting pressure, the more the blade is secured against unintentional folding back.”

“[…] The advantages of the new knife, the handling of which does not differ much from the usual one and therefore does not require any change of the user, are therefore the following: The folding up of the blade does not require any appreciable effort, the safety catch is automatically produced by the cutting pressure, and its strength is independent of the degree of any wear, which is hardly to be expected due to the favorable construction, so that the danger of loosening of the connection between blade and hilt and any resulting wobbling of the blade is excluded.”

We do not know if Exel was working with a knife company. His idea still seems very modern, especially in view of the ever stricter bans on knives with a mechanical locking mechanism. Maybe someone picks up on his idea?

The drawings from Austrian patent 185267, applied for on 15 October 1954 by

dipl. Ing. Theodor Exel, and granted on 15 July 1955.